Teaching Elevator

Teaching, training and assessment are three in one

Customized teaching equipment

In the traditional elevator industry homogenization competition more and more fierce today, Shanghai koms has been exploring the transformation of elevator manufacturing enterprise from traditional manufacturing industry.We can do that school is factory, factory is school, students are workers, workers are students, graduation means employment, for the growing elevator market at domestic and abroad to train professional and technical personnel;

The pilot project for One Belt And One Road is also supported by both governments.

This is a cause that benefits the society and can last forever. As long as human society exists, this cause will never end.

Industry status analysis

Throughout the development process of China's elevator industry, from reform and opening up to today, the elevator industry has unconsciously gone through a development process from scratch, from many to many, from many to fine. With the great changes in the housing market, China has become the largest and fastest-growing elevator market in the world. As China is one of the most active real estate markets in the world, China's elevator market is far from saturated. In the next 50 years, the new housing area in China will reach 20 billion square meters. At present, the state stipulates that elevators should be installed in high-rise buildings over 20 meters, and the demand for elevators in the future residential market will be very large.

(1) A new round of long bright spots in the wide and deep business of elevator field

(2) Elevator maintenance business becomes the second growth point of the elevator industry

(3) Another growth highlight of the scarcity of professional maintenance talents in the elevator industry

Industry outlook optional

However, the training of elevator engineering and technology professionals lags behind the development of the industry. In particular, the transportation of "fresh blood" of professional technical personnel engaged in the technical design, installation, and maintenance of elevator application level, no matter the quality of personnel or the number of personnel, can not meet the needs of industry development and has become an important factor restricting the development of the industry

According to the national shortage of 500000 elevator technical talents and 1288 Vocational Colleges (latest data in 2016), the feasibility of school-enterprise cooperation training is promising.

SCHOOL ENTERPRISE COOPERATION

Cooperation mode

The enterprise assists the school in applying for special funds (project special funds and equipment special funds), and realizes the win-win value-added of the enterprise and the school through the way that the school purchases services from the enterprise and increases the teaching and training equipment

The school is responsible for providing venue, enrollment, basic teaching equipment and teachers

School enterprise cooperation, tripartite benefits

In view of the fact that the treatment of elevator technical workers is low, the working environment is poor, and the talents can not be retained, we should change our thinking: using the manufacturing advantages of the factory and the technical advantages of the sales and after-sales outlets around the world, we should provide components, technology, and even processing equipment, assemble in the training workshop, and lead and encourage students to create markets and start businesses together.

Ar teaching schedule

| Serial number | Type | Course name | |

|

1 | Principle class | Digital textbook of vertical ladder principle (PDF) |

| Straight ladder principle course (video) | |||

| Straight ladder principle course (scrum courseware) | |||

| 2 | Installation class | Installation of traction vertical ladder in the organic room (with scaffold) (video) | |

| Course v1.0 (PC end simulation) of traction vertical ladder installation (with scaffold) in organic room | |||

| Installation of traction vertical ladder in the organic room (without scaffold) (video) | |||

| Course v1.0 (PC end simulation) of traction vertical ladder installation in the organic room (no scaffold | |||

| 3 | Maintenance | Maintenance course of traction vertical ladder in the organic room (video) | |

| Course v2.0 for maintenance of traction type vertical ladder in the organic room (PC end simulation) | |||

| V2.0 (VR simulation) course of traction vertical ladder maintenance in the organic room |

Assessment Console for Fault Setting of Escalator(KC-KJ(HJFT)-VF(HL))

|

Function introduction |

| The elevator fault setting system can automatically / manually set the electrical fault through the upper computer control, the signal is transmitted to the computer through communication, and the operator can troubleshoot the physical elevator according to the elevator fault prompt. After troubleshooting, the upper computer software will automatically display the fault reset and record the score of this assessment item. The system is convenient, fast, and easy to operate. |

Technical parameters:

1. Control platform: computer

2. Power supply: AC220V

3. Overall capacity: ≤ 0.5KW

4. Fault box specification: 400 * 200 * 600mm

5. Net weight: 20kg

6. Control mode: RAM fault board, communication transmission

7. Standard fault points: 24 points/group

8. Expandable fault points: any extension

9. Safety protection measures: leakage protection and safety meet relevant national standards

10. Applicable object: Monec nice3000new controller, V / F control of gantry crane

Automatic Pedestrian Training and Assessment System(KC-FT-VF(L))

|

Product introduction |

| The pedestrian walkway training equipment is suitable for the elevator technical professional students of Vocational Colleges and secondary vocational colleges to carry out the practical training of escalator operation and maintenance. The training equipment includes industrial real escalator step pedal system, handrail belt system, traction machine system, equipment bench, safety detection system, electrical control system, fault detection system, etc. |

Technical parameters

(1) Input power supply: three-phase four-wire (or three-phase five-wire) AC380V ± 10%, power frequency 50Hz

(2) Working environment: the ambient temperature range is – 5 ℃ – + 40 ℃, and the relative humidity is less than 85% (25 ℃).

(3) Overall capacity: < 7.5kVA

(4) Boundary dimension: 7500mm (L) × 2500mm (W) × 2980mm (H)

(5) Lifting height: 1000mm-1500mm

(6) Control mode: PLC + variable frequency self starting control.

(7) Monitoring system: real-time monitoring of voltage and current conditions.

(8) Fault module: it has 30-bit common electrical fault simulation setting function.

(9) Safety protection: it has the protection functions of grounding, overload, overcurrent, and leakage current, and the safety conforms to the national standards.

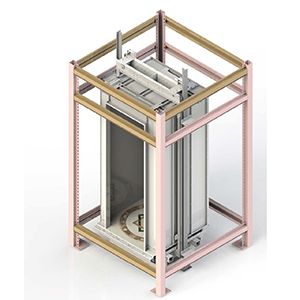

Escalator training and assessment system(KC-FT-VF(H))

|

Product introduction |

| The teaching elevator is based on the most common commercial elevator structure, which is made of real commercial elevator components. Its structure is exactly the same as the actual elevator, in fact, it is a miniaturized elevator. Because almost all parts are made of commercial elevator components, it is easy to observe and understand the whole elevator structure. At the same time, each action of the elevator in the process of operation is also clear at a glance, and it can also be repeatedly practical operation. So that students can more intuitive, thorough understanding, master the structure of the elevator and its active principle, to achieve the effect of twice the result with half the effort. |

Technical parameters

(1) Working power supply: three-phase five-wire AC380V ± 7.5%, power frequency 50Hz

(2) Card size: 1200 × 1000 × 2150 (L × w × h)

(3) Hall door net size: 700 × 2000mm (w × h)

(4) Middle separate door type

(5) Centralized selection frequency conversion control mode

(6) Safety protection measures: grounding protection, over-current, overload, leakage protection, anti-falling and anti-collision protection functions, in line with the relevant national standards.

(7) Maximum power consumption ≤ 4.5kw

(8) Steel plate bending steel structure, equipped with safety guardrail, 2-story station, pit 1500, load 630kg, traction ratio: Organic room 1:1 (inorganic room, 2:1 optional)

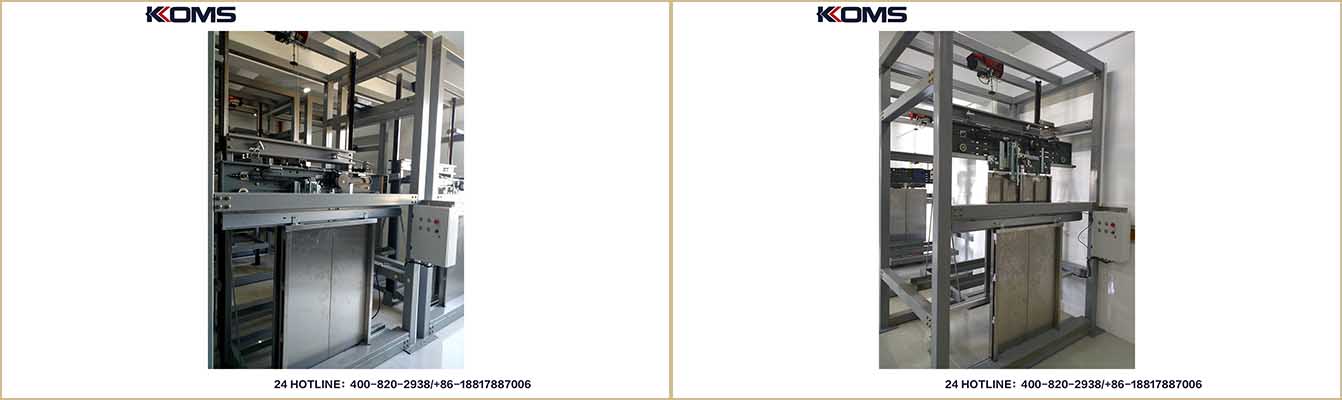

Vertical Elevator Training and Assessment System(KC-KJ(HJ)- 630VF)

|

Product introduction |

| The teaching elevator is based on the most common commercial elevator structure, which is made of real commercial elevator components. Its structure is exactly the same as the actual elevator, in fact, it is a miniaturized elevator. Because almost all parts are made of commercial elevator components, it is easy to observe and understand the whole elevator structure. At the same time, each action of the elevator in the process of operation is also clear at a glance, and it can also be repeatedly practical operation. So that students can more intuitive, thorough understanding, master the structure of the elevator and its active principle, to achieve the effect of twice the result with half the effort. |

Technical parameters

(1) Working power supply: three-phase five-wire AC380V ± 7.5%, power frequency 50Hz

(2) Car size: 1200 × 1000 × 2150 (L × w × h)

(3) Hall door net size: 700 × 2000mm (w × h)

(4) Middle separate door type

(5) Centralized selection frequency conversion control mode

(6) Safety protection measures: grounding protection, over-current, overload, leakage protection, anti-falling and anti-collision protection functions, in line with the relevant national standards.

(7) Maximum power consumption ≤ 4.5kw

(8) Steel plate bending steel structure, equipped with safety guardrail, 2-story station, pit 1500, load 630kg, traction ratio: Organic room 1:1 (inorganic room, 2:1 optional)

Car door training equipment (kc-jm)

|

Car door training equipment (kc-jm) |

| 1. Cognition of car door structure principle 2. Installation and operation of car door and relevant requirements 3. Parameter debugging of elevator door controller 4. Installation and adjustment of elevator car door sill 5. Cognition of car door related national standards 6. Boundary dimension: 1200 (L) × 900 (s) × 1865 (H) |

Car roof training equipment (kc-jd)

|

Car roof training equipment (kc-jd) |

| 1. Safety awareness of entering and leaving car roof 2. Operation mode of entering car roof 3. Operation mode of exiting car roof 4. Installation and adjustment of elevator landing door upper sill device 5. Installation and adjustment of elevator landing door panel 6. Installation and adjustment of elevator landing door frame 7. Installation and adjustment of sill 8. Cognition of elevator maintenance box 9. Boundary dimension: 1800 (L) × 1650 (s) × 2460 (H) |

Car training equipment (kc-jx)

|

Car training equipment (kc-jx) |

| 1. Installation and adjustment of the car frame 2. Car assembly and cognition 3. Installation and adjustment of the guide shoe 4. Guide rail installation and adjustment 5. Installation and adjustment of guide rail bracket 6. Cognition of car roof operation in elevator maintenance 7. Boundary dimension: 1900 (L) × 1900 (s) × 2900 (H) |

Guide rail training equipment (kc-dg)

|

Guide rail training equipment (kc-dg) |

| 1. Installation and verification of elevator guide rail 2. Installation and adjustment of guide rail bracket 3. Elevator guide rail installation tools andUsage of testing tools 4. National standard cognition of elevator guide rail and installation 5. Boundary dimension:1400(L)*1400(S)*4000(H) |

Hall door training equipment (kc-tm)

|

Hall door training equipment (kc-tm) |

| 1. Installation and adjustment of elevator landing door upper sill device 2. Installation and adjustment of elevator landing door panel 3. Installation and adjustment of elevator landing door frame 4. Installation and adjustment of sill 5. Landing door sill coordinated with car door training equipment Training on adjustment of the gap between the car door sill 6. Cognition of related national standards 7. Boundary dimension: 1200 (L) × 900 (s) × 1660 (H) |

Rope head training equipment (kc-st)

|

Rope head training equipment (kc-st) |

| 1. Cognition of installation method for taper sleeve of wire rope head 2. Installation operation of taper sleeve of wire rope head 3. Cognition of relevant national standards on the relationship between wire rope and rope wheel 4. Boundary dimension: 1450 (L) × 800 (s) × 1665 (H) |

Traction machine training equipment (kc-jm)

|

Traction machine training equipment (kc-jm) |

| 1. Installation and adjustment of the traction machine; 2. Installation and adjustment of the base; 3. Cognition of main components of traction machine; 4. Cognition of relevant national standards of traction machine; 5. Boundary dimension: 1200 (L) × 800 (s) × 2060 (H) |