Clean Elevator

Intelligent voice clean elevator

Shanghai KOMS clean (dust-free) series elevators fully refer to the provisions of the American Standard fed-std-209e. KOMS has the qualification of clean elevator and the performance of clean elevator. Clean elevator (dust-free elevator) is especially suitable for the workshop of electronic, photoelectric, pharmaceutical, biological, fine chemical factory, instrument laboratory, spraying workshop and other places with clean requirements. It is applicable to the environment with a cleanliness requirement of 100-100000; it has good cooperation foundation with medical device factories, hospitals (including design units) and clean equipment manufacturers.

UV automatic disinfection system

Food grade stainless steel is used for elevator car panel.

Quartz material, ozone free sterilization tube (254nmuvc wavelength).

Full range, no dead angle for automatic disinfection of elevator car.

Free setting of disinfection duration and time period.

Integrated body sensor, double protection (novel coronavirus and SARS) can effectively kill single strand RNA (RNA) viruses.

Non contact elevator scheme

In addition to the regular elevator button, the voice call function is added.

• excellent recognition performance, wake up successfully within 3 meters, recognition rate > 95%.

• completely offline speech recognition, no network required, zero response delay.

Wake up voice through voice call standard: "kangmeishi kangmeishi" can wake up voice call function (it can also be customized and developed according to user needs, such as Mandarin, English and Cantonese versions).

The intelligent voice controlled customized elevator with the function of clean protection and sterilization is the company's main series of products, which has applied a number of technical innovations:

1. Automatic purification

The car is equipped with a car air sterilization and purification system to provide an air purification unit for the local clean working environment of the car. The car's self - cleaning system adopts physical and biochemical treatment methods.

2. Phonetic system

Cop adds voice prompt, which is realized by voice call module.

3. Automatic disinfection

Negative ion generator and ultraviolet lamp in the fan.

In addition, novel coronavirus automatic disinfection function is realized. It can automatically sterilize the elevator car and lift human body sensor to achieve double protection. It can effectively kill single strand RNA (RNA) virus (such as new coronavirus and SARS). In addition to the conventional elevator button, the voice call function is added, with excellent recognition performance. It can wake up successfully within 3 meters, with recognition rate > 95%, completely offline voice recognition, etc.

The project design of this all-round disinfection of the clean elevator can effectively prevent the infection of virus. With the improvement of public health requirements, the clean elevator will be paid more and more attention by the market. It is believed that the project will have a considerable market prospect in the future.

4. Air duct type self purification system

The air duct type self purification system equipment can be flexibly installed at the top or outside side according to the actual situation of the site. According to the pollution source, the air outlet of the purification equipment can be installed at the top or the bottom of the equipment. Through the filter unit of the air duct type self purification system, the purified air is still used as fresh air to supplement the elevator interior, so that the elevator car always maintains a positive pressure. This is only a physical treatment method, Kangmeishi clean elevator also has a biochemical treatment method, that is, through a specific biochemical treatment method to smash bacteria and microorganisms into molecular atoms, and at the same time through the release of ozone, ultraviolet sterilization and other traditional sterilization and disinfection methods, to achieve the role of air purification, sterilization and detoxification.

| Standard gantry civil drawing parameters | |||||||||||||||

| load (kg) |

speed (m/s) |

cabin size | Door Type | Door opening | Hoist-way Size | Max R (mm) |

Max D (mm) |

P (kw) |

DBGRB (mm) |

||||||

| CW (mm) |

CD (mm) |

CH (mm) |

DW (mm) |

DH (mm) |

HW (mm) |

HD (mm) |

Min S (mm) |

Min K (mm) |

|||||||

| 260 | 0.4 | 800 | 1100 | 2150 | Side Opening | 700 | 2000 | 1400 | 1450 | 500 | 2800 | 1200 | 2400 | 0.9 | 1500 |

| 320 | 900 | 1200 | 800 | 1500 | 1550 | 1.1 | |||||||||

| 400 | 1000 | 1200 | 800 | 1600 | |||||||||||

| 320 | 900 | 1200 | Center Opening Four Panels door | 700 | 1500 | 1500 | |||||||||

| 400 | 1000 | 1200 | 800 | 1600 | |||||||||||

| 320 | 900 | 1200 | Center Opening door | 650 | 1500 | 1450 | |||||||||

| 400 | 1000 | 1200 | 700 | 1600 | |||||||||||

| 630 | 0.5 | 1200 | 1300 | Side Opening | 800 | 1900 | 1650 | 600 | 3000 | 2.1 | |||||

| Center Opening Four Panels door | 1600 | ||||||||||||||

| Center Opening door | 1550 | ||||||||||||||

| Remark:CW:cabin width, CH:cabin Height, DW:door width, DH:door hight, HW:hoist-way width, HD:hoist-way Depth, S:pit depth, K:overhead height, R:traveling height, D:pitch of floor | |||||||||||||||

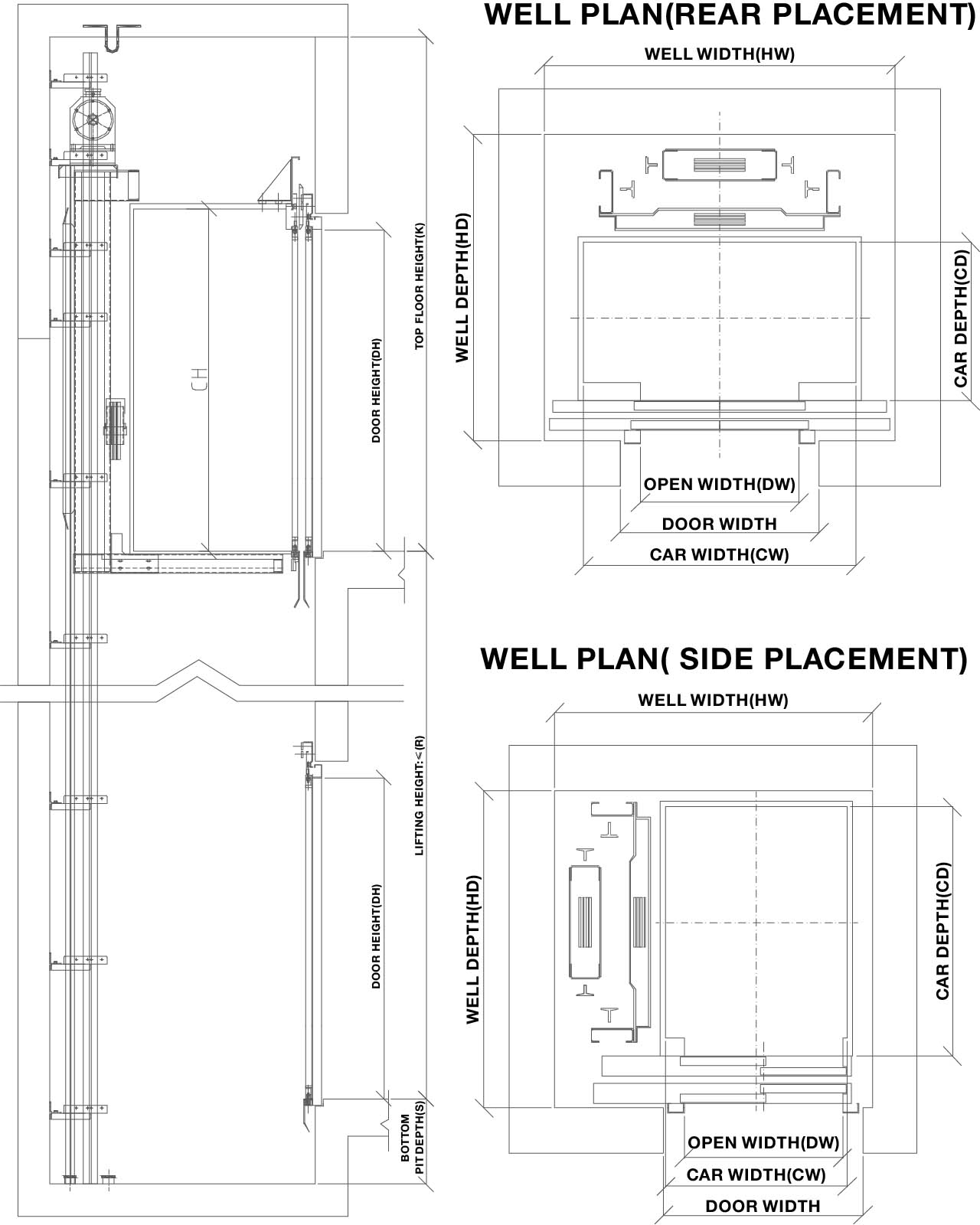

| Parameters of standard knapsack frame civil drawing | ||||||||||||||||

| load (kg) |

speed (m/s) |

Arrangement mode | cabin size | Door Type | Door opening | Hoist-way Size | Max R (mm) |

Max D (mm) |

P (kw) |

DBGRB (mm) |

||||||

| CW (mm) |

CD (mm) |

CH (mm) |

DW (mm) |

DH (mm) |

HW (mm) |

HD (mm) |

Min S (mm) |

Min K (mm) |

||||||||

| 260 | 0.4 | Postposition | 1200 | 700 | 2150 | Center Opening door | 700 | 2000 | 1550 | 13550 | 300 | 2800 | 1200 | 2400 | 0.9 | 1500 |

| Lateral position | 800 | 1100 | Automatic side door opening | 1400 | 1400 | |||||||||||

| 320 | Postposition | 1200 | 900 | Center Opening door | 1550 | 1550 | 1.1 | |||||||||

| Lateral position | 900 | 1200 | Automatic side door opening | 800 | 1500 | 1500 | ||||||||||

| 400 | Postposition | 1200 | 1000 | Center Opening door | 700 | 1550 | 1650 | |||||||||

| Lateral position | 1000 | 1200 | Automatic side door opening | 800 | 1600 | 1500 | ||||||||||

| Remark:CW:cabin width, CH:cabin Height, DW:door width, DH:door hight, HW:hoist-way width, HD:hoist-way Depth, S:pit depth, K:overhead height, R:traveling height, D:pitch of floor | ||||||||||||||||

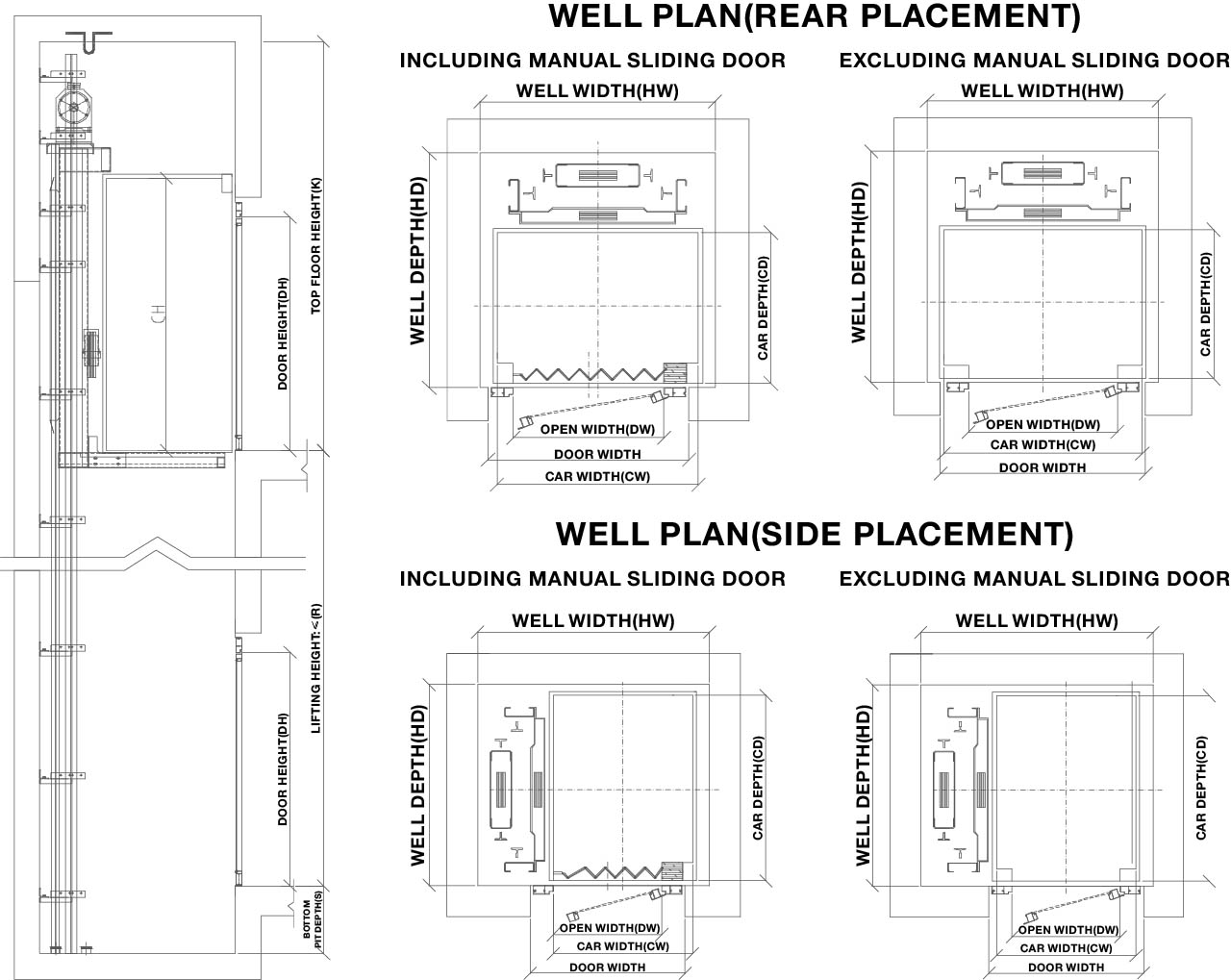

| Parameters of backpack frame villa elevator(manual door) | ||||||||||||||||

| load (kg) |

speed (m/s) |

CWT Position |

cabin size | Opening Type | Door opening | Hoist-way Size | Max R (mm) |

Max D (mm) |

P (kw) |

DBGRB (mm) |

||||||

| CW (mm) |

CD (mm) |

CH (mm) |

DW (mm) |

DH (mm) |

HW (mm) |

HD (mm) |

Min S (mm) |

Min K (mm) |

||||||||

| 260 | 0.3 | REAR | 1100 | 800 | 2150 | Excluding manual car door | 800 | 2000 | 1300 | 1300 | 300 | 2800 | 12000 | 2400 | 0.9 | 1500 |

| Including manual car door | ||||||||||||||||

| SIDE | 800 | 1100 | Excluding manual car door | 700 | 1400 | 1200 | ||||||||||

| Including manual car door | 650 | |||||||||||||||

| 320 | REAR | 1200 | 900 | Excluding manual car door | 800 | 1400 | 1.1 | |||||||||

| Including manual car door | 900 | |||||||||||||||

| SIDE | 900 | 1200 | Excluding manual car door | 800 | 1500 | 1300 | ||||||||||

| Including manual car door | 700 | |||||||||||||||

| 400 | REAR | 1200 | 1000 | Excluding manual car door | 800 | 1550 | 1650 | |||||||||

| Including manual car door | 900 | |||||||||||||||

| SIDE | 1000 | 1200 | Excluding manual car door | 800 | 1600 | 1300 | ||||||||||

| Including manual car door | 800 | |||||||||||||||

| Remark:CW:cabin width, CH:cabin Height, DW:door width, DH:door hight, HW:hoist-way width, HD:hoist-way Depth, S:pit depth, K:overhead height, R:traveling height, D:pitch of floor | ||||||||||||||||